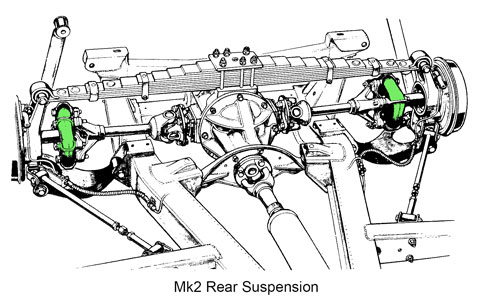

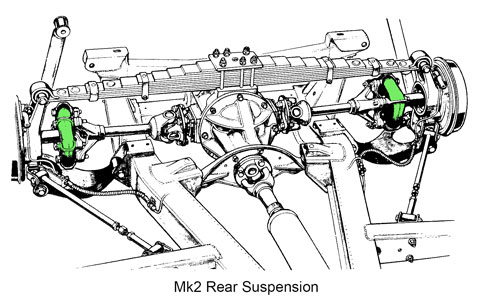

GT6 Rotoflex Doughnuts

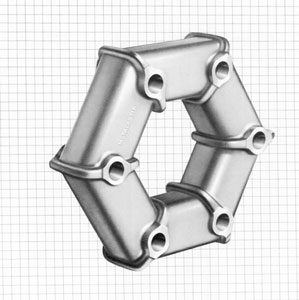

The suspension fitted to the GT6 Mk2, the Vitesse Mk2 and the early GT6 Mk3 was fitted with 'Rotoflex' rubber and metal couplings or doughnuts. These were originally made by the Polymer Engineering Division of Dunlop in Leicester, under the trade name of 'Metalastik'. These couplings were widely used in various applications, including Triumph's own 1300, the Hillman Imp, and on racing cars including the Brabham-Repco of the 1966 World Champion driver Jack Brabham and the Lotus Coventry Climax of Jim Clarke, the 1965 Champion. According to the original Metalastik brochure (to see the full brochure click here), they:

1. Accommodate large angular and axial displacements with minimum resistance.

2. Reduce torsional vibration and noise.

3. Absorb torque fluctuations.

4. Replace mechanical joints, eliminating lubrication and metal to metal wear.

5. Require no servicing.

6. Unaffected by dust, grit and moisture.

Below is the Dunlop Polymer Engineering factory in Evington Valley Road, Leicester where they were made (the author worked there in the 1970s and remembers seeing pallets of couplings). This division of Dunlop is now part of Trelleborg AB in Sweden.

Unfortunately, many replacement Rotoflex couplings have been found to be of poor quality & last only a short time. I had some GM ones, and they only lasted around 25k miles, which I believe is actually quite good! According to some, you can still drive on them even when the the segments delaminate and shear apart from one another which was certainly the case with mine! However this does not mean they were safe, and new genuine Metalastik couplings have now been fitted to my GT6, I bought them some years ago when they were plentiful and cheap. These should last much longer, some claim perhaps from 15 to 30 years (depending on how the car is driven). The best modern replacements come from the company which purchased the Metalastik company & continues to brand their couplings as Metalastik, but I believe they are very expensive, if you can find them. The correct Metalastik rotoflex coupling for a GT6 is part number 21/979/1, according to the brochure the specification is as follows:

Overall Diameter (Assembled) : 6.38" (162mm)

P.C.D. of Bolt Centres (Assembled) : 4.44" (113mm)

Diameter of Fixing Holes : 0.52" (13mm)

Width Across Metal Faces : 1.84" (47mm)

Diameter of Rubber Cross Section : 1.44" x 1.66" (37mm x 42mm)

Torque : Normal 350 lb.ft; Max 610 lb.ft

Torsional Stiffness : 33 lb.ft/deg

Axial Stiffness : 590 lb.in

Normal Continuous Axial Deflection : 0.25"

Normal Continuous Cardan Deflection : 5 deg

A Metalastik advert can be seen here. Views of the factory can be seen by clicking on this link: 28dayslater. To see an original letterheading click here.

Fitting Rotoflex couplings

These are not difficult to replace, per se, however rebuilding the rear hub is. According to David Pearson (Canley Classics) "Setting the wheel bearing end float on a rotoflex car (standard or CV conversion) is critical. If you haven't done one before and aren't armed with a factory workshop manual, a pile of shims, spacers, and a decent set of tools then we would suggest getting a professional involved". I used Mike Papworth (seen below, working on my Rotoflex hub in his workshop). The metal band can be seen in place, this should only be removed when installed on the car.

CV Conversions

As even the best Rotoflex couplings have a limited life, some people have replaced them with a CV (constant velocity) conversion which is supposed to last much longer. Below is the Canley Classics version, although other Triumph parts suppliers sell them too. Expect to pay £500 to £600, though! Ironically they were originally advertised as replacements for CV joints, to see such an advert click here.

![]()