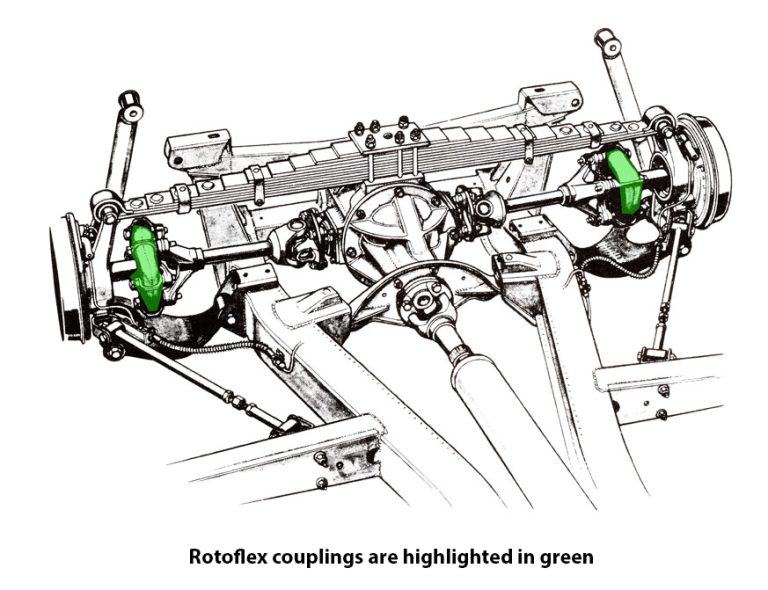

The Rotoflex couplings (or doughnuts) fitted to the GT6 Mk2, the Vitesse Mk2 and the early GT6 Mk3 were made by a subsidiary of Dunlop called the Polymer Engineering Division in Leicester under the trade name ‘Metalastik’. These flexible couplings were first used in the half-shafts of Lotus cars, providing smooth and quiet power transmission. Other Metalastik bonded rubber to metal components supplied to the UK car industry included engine and gearbox mounts, anti-roll bar bushes, and other rubber-based components for suspension systems, such as those used in front wheel hubs, springs, and other isolators. The couplings were widely used in various other applications, including Triumph’s own 1300, the Hillman Imp, and on racing cars including the Brabham-Repco of the 1966 World Champion driver Jack Brabham and the Lotus Coventry Climax of Jim Clarke, the 1965 Champion.

According to the Metalastik brochure, they:-

1. Accommodate large angular and axial displacements with minimum resistance.

2. Reduce torsional vibration and noise.

3. Absorb torque fluctuations.

4. Replace mechanical joints, eliminating lubrication and metal to metal wear.

5. Require no servicing.

6. Are unaffected by dust, grit and moisture.

What’s not to like! However they were heavy and expensive to make, and had a limited lifespan, particularly the copies made by other companies. Later MK3 GT6s reverted to the swing spring of the earlier cars, but with a clever modification. Rather than having a rigidly-mounted transverse leaf spring, only the lower leaf of the spring is bolted onto the differential. The remaining leaves are mounted in a box with a pivot through it so that the upper leaves are ‘floating’. This results in the tendency for sudden oversteer to be greatly reduced and the car feels more ‘sure-footed’ when being driven quickly.

On the right (or below) is the Dunlop Polymer Engineering factory in Evington Valley Road, Leicester where Rotoflex couplings were made (the author worked there in the 1970s and remembers seeing pallets of couplings). This division of Dunlop is now part of Trelleborg AB in Sweden. The factory closed in 1988 but is still standing.

The story of how the Metalastik company came about is quite fascinating! The company was founded by Matt Goldschmidt (subsequently anglicised to Mac Goldsmith) just before WW2. Born in Frankfurt, he fled from Nazi Germany to the UK at the beginning of 1937.

An accomplished mechanical engineer and businessman he founded the new company in partnership with the John Bull Rubber company. The company started a completely new process for bonding rubber to metal which was subsequently used in a wide variety of anti-vibration devices which came into their own in all the armed services during the War.

Goldsmith always considered the granting of a Queen’s Award to Industry to Metalastik in 1967 for their innovative components on the London underground trains, as the highlight of his professional career. In 1958 the company wa sold to the Dunlop Rubber Co. Hw later became a Freeman of the City of Leicester and was also granted an honorary PhD from Leicester University. He died in 1983 aged 80.

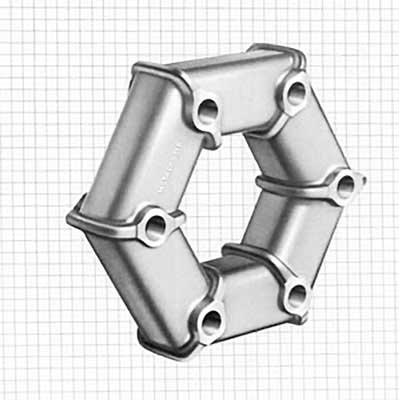

Unfortunately, many replacement Rotoflex couplings have been found to be of poor quality & last only a short time. I had some GM ones, and they only lasted around 25k miles, which I believe is actually quite good! According to some, you can still drive on them even when the the segments delaminate and shear apart from one another which was certainly the case with mine! However this does not mean they were safe, and new genuine Metalastik couplings have now been fitted to my GT6, I bought them some years ago when they were plentiful and cheap. These should last much longer, some claim perhaps from 15 to 30 years (depending on how the car is driven). The best modern replacements come from the company which purchased the Metalastik company & continues to brand their couplings as Metalastik, but I believe they are very expensive, if you can find them. The correct Metalastik rotoflex coupling for a GT6 is part number 21/979/1, according to the brochure the specification is as follows:

- Overall Diameter (Assembled) : 6.38″ (162mm)

- P.C.D. of Bolt Centres (Assembled) : 4.44″ (113mm)

- Diameter of Fixing Holes : 0.52″ (13mm)

- Width Across Metal Faces : 1.84″ (47mm)

- Diameter of Rubber Cross Section : 1.44″ x 1.66″ (37mm x 42mm)

- Torque : Normal 350 lb.ft; Max 610 lb.ft

- Torsional Stiffness : 33 lb.ft/deg

- Axial Stiffness : 590 lb.in

- Normal Continuous Axial Deflection : 0.25″

- Normal Continuous Cardan Deflection : 5 deg

A Metalastik advert can be seen by clicking here.

Fitting Rotoflex couplings

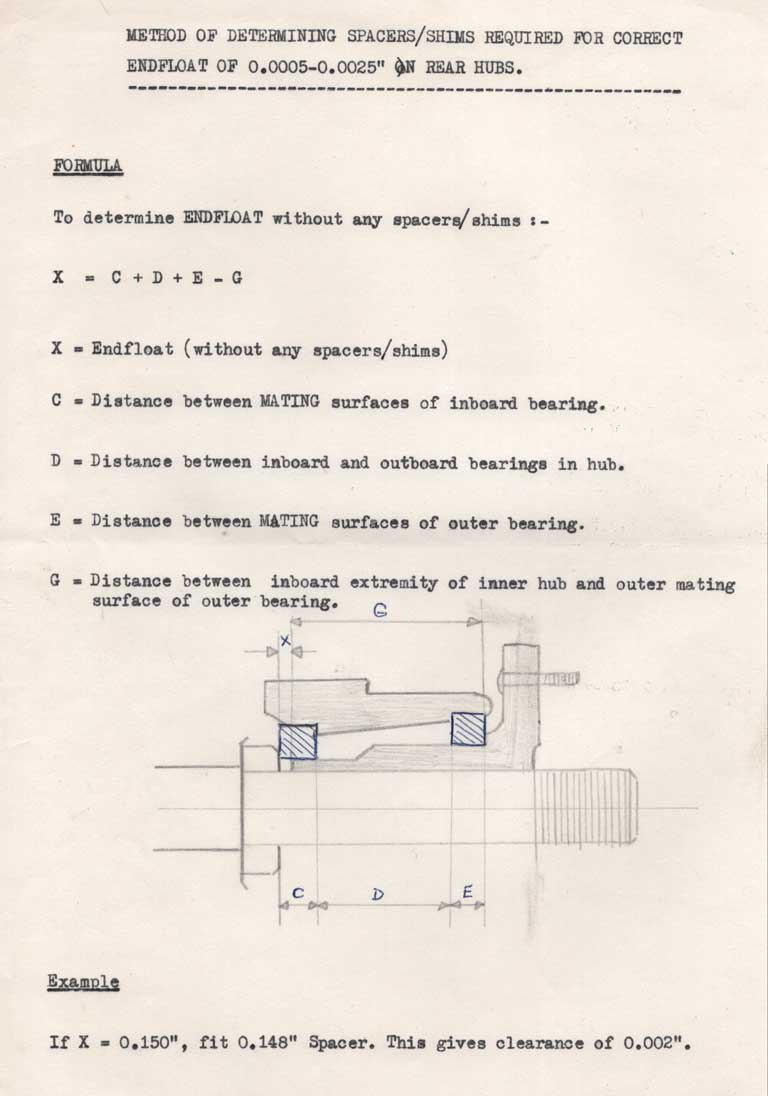

These are not difficult to replace, per se, however rebuilding the rear hub is. According to David Pearson (Canley Classics) “Setting the wheel bearing end float on a rotoflex car (standard or CV conversion) is critical. If you haven’t done one before and aren’t armed with a factory workshop manual, a pile of shims, spacers, and a decent set of tools then we would suggest getting a professional involved”.

When I did it in 1981/2 it I created the document below (with a view to writing an article).

More recently I used Mike Papworth (seen below, working on my Rotoflex hub in his workshop). The metal band can be seen in place, this should only be removed when installed on the car.

CV Conversions

As even the best Rotoflex couplings have a limited life, some people have replaced them with a CV (constant velocity) conversion which is supposed to last much longer. I think these were first introduced by Canley Classics but they have now discontinued them. However Rimmer Bros. (and others) offer a conversion kit for an eye watering £780! Click here if you don’r believe me!